Project Overview

A commercial lift station experienced recurring operational issues after repairs by a general property maintenance contractor. Although the work was presented as a full repair, the station continued to show signs of failure and posed a risk of long-term equipment damage. A comprehensive inspection was requested to identify the root causes and restore reliable operation.

Initial Conditions

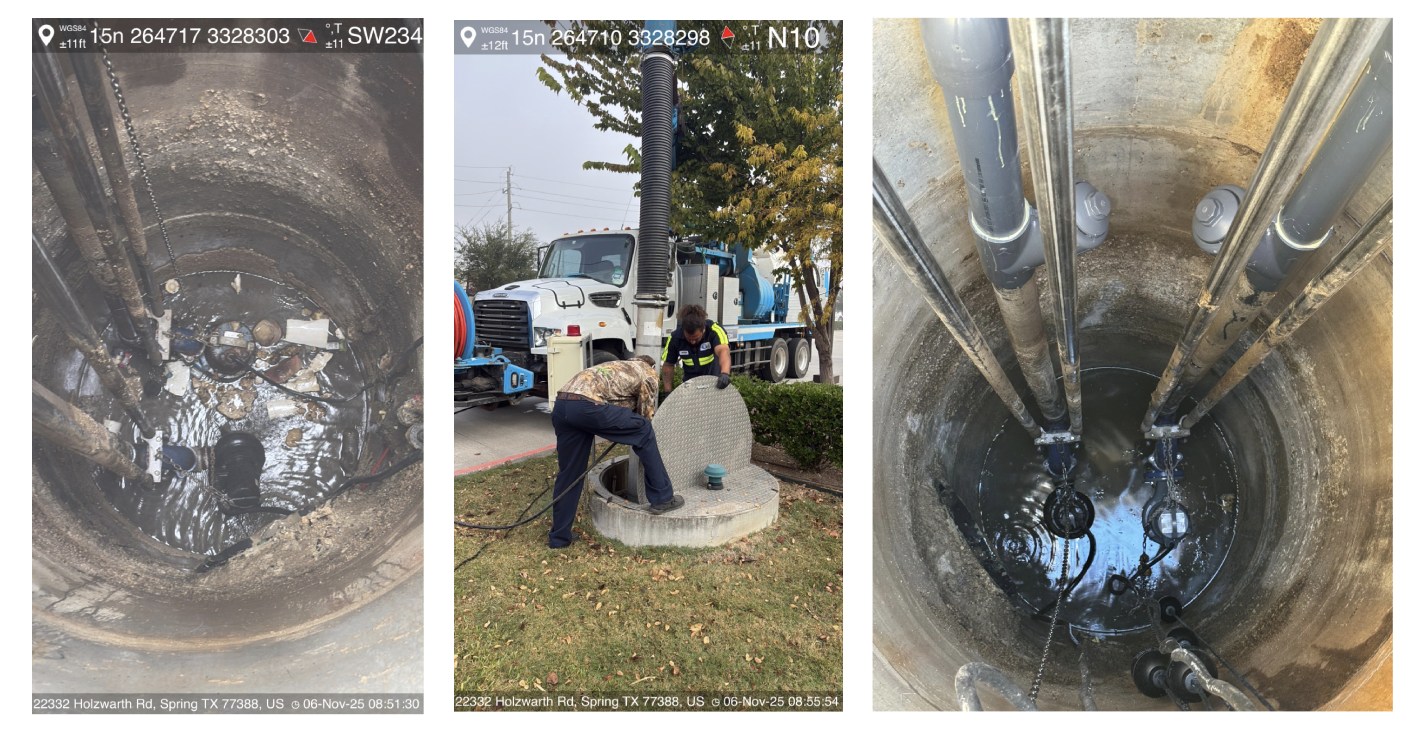

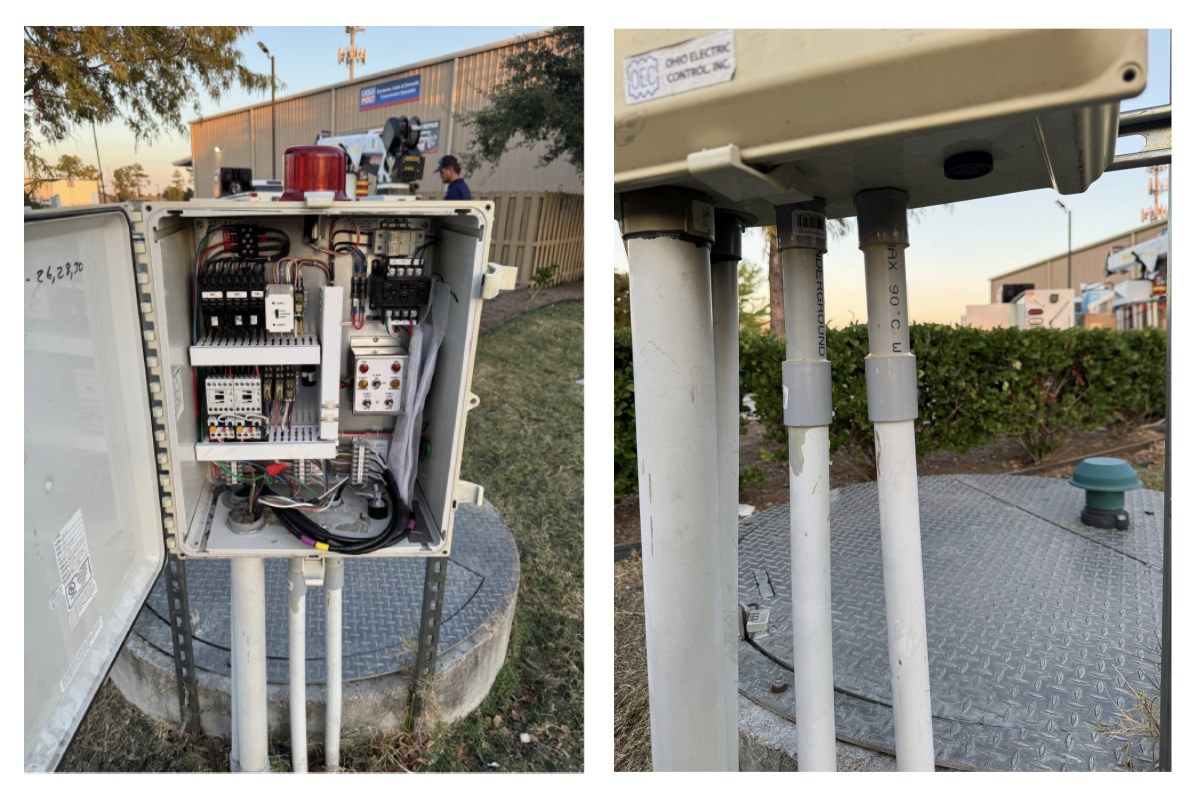

Upon arrival, several critical deficiencies were immediately identified. Required check valves had been removed and replaced with shutoff valves, eliminating essential backflow protection and increasing the risk of premature pump failure. Incorrect piping materials were used that could not withstand startup pressures or water hammer. One pump was found nonfunctional and lying on its side in the wet well, despite reports that both pumps were operational. In addition, the electrical conduit to the control panel was detached, allowing moisture and pests to enter and significantly shorten the lifespan of the panel components.

Check valves were replaced with shutoff valves using no-hub connectors, which cannot withstand high start pressures or water hammer.

One pump was nonfunctional and improperly positioned, despite claims both pumps were operational.

Detached conduit exposed the control panel to moisture and pests, potentially shortening its lifespan.

Challenges Identified

-

Loss of backflow protection due to improper valve selection

-

Incorrect piping materials for high-pressure lift station applications

-

Failed and improperly seated pump within the wet well

-

Electrical exposure caused by damaged conduit

-

Malfunctioning float controls

-

Debris accumulation in the wet well poses a risk to new equipment

Scope of Work

The repair process began with removing the improperly installed valves and replacing them with the correct ball check valves. Damaged piping and fittings were replaced with appropriate materials designed for lift station conditions. The failed pump was replaced, and the wet well was fully cleaned to remove debris that could damage new equipment. The existing pump was reseated correctly, and new float controls were installed. Electrical repairs included cleaning the control panel, replacing damaged relays, and repairing the conduit to prevent future moisture and pest intrusion.

Valves and piping were replaced, pumps reseated, and the wet well cleaned to prevent future failures.

Control panel cleaned, relays replaced, and conduit repaired to restore electrical protection.

Results

Following repairs, a full system inspection and operational test were completed. The lift station was successfully returned to service with proper flow control, reliable pump operation, and restored electrical protection. The system is now configured to operate as designed, reducing the risk of future failures and extending the equipment’s life.

Lift station successfully restored to full operational condition.

Key Takeaway

Lift stations are complex systems that require specialized expertise. This project demonstrates how improper repairs can lead to increased costs and system risk, while correct installation, materials, and maintenance restore reliability and protect long-term infrastructure performance.

Reach out to any of our offices if you would like one of our team members to come out and review your lift stations with you.