AQUA-PONIC™

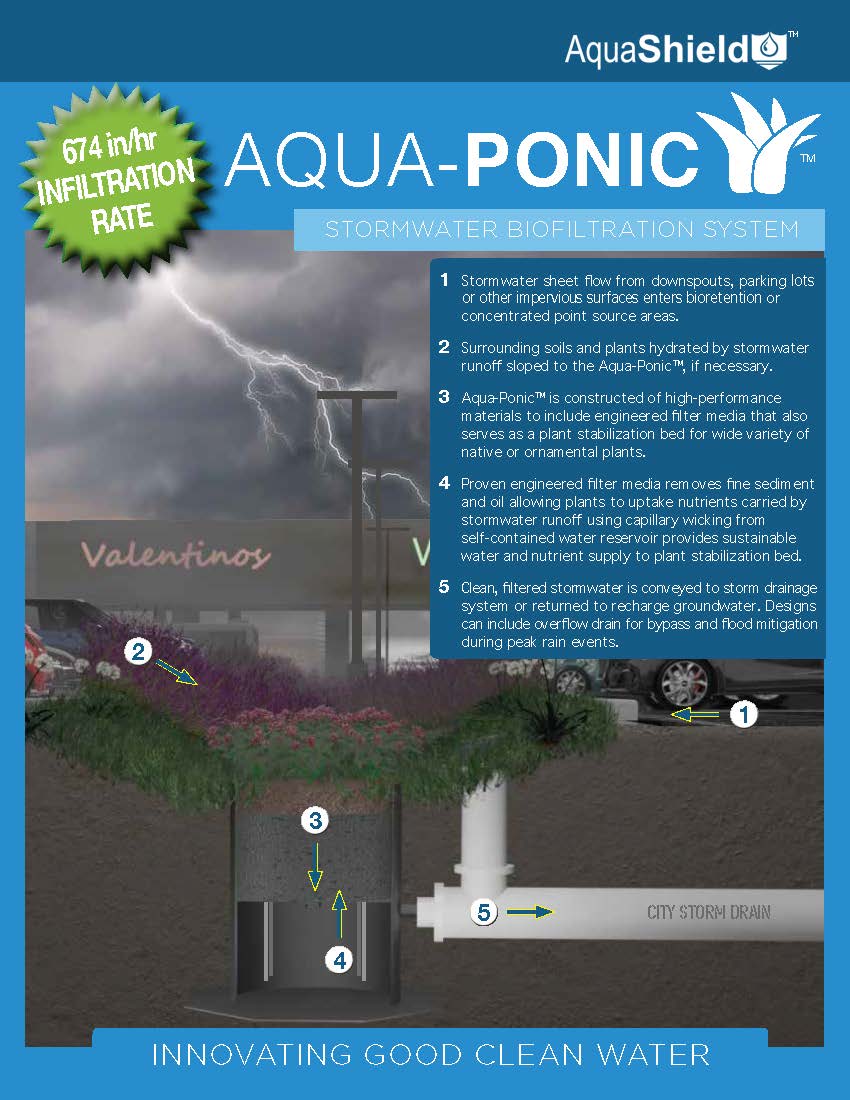

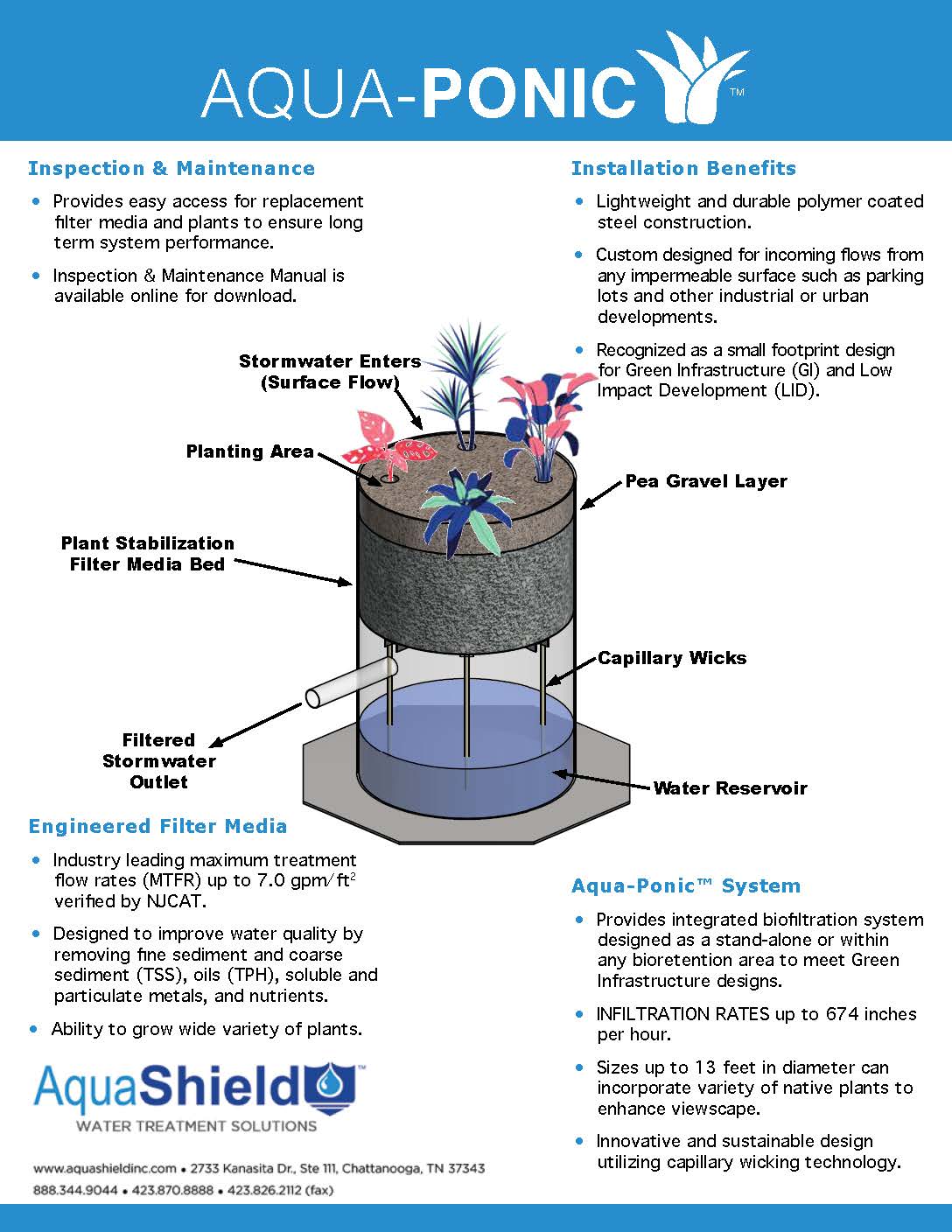

Biofiltration SystemAqua-Ponic™ Biofiltration System is the latest technology to provide a modular proprietary, permanent, post-construction biofiltration system. The innovative Aqua-Ponic™ design is unique when compared to other manufactured biofilters in terms of filtration, treatment flow rates and importantly, plant sustainability. While filtration is common to all of these systems, the Aqua-Ponic™ combines filtration with the principles of hydroponics – a method of hydroculture for growing plants without soil by instead using mineral nutrient solutions in a water solvent. That is, the Aqua-Ponic™ uses stormwater runoff as a nutrient asset instead of a liability. Terrestrial plants may be grown with only their roots exposed to the nutrient liquid, or the roots may be physically supported by an inert bio-medium.

A distinct advantage of the Aqua-Ponic™ Biofiltration System pertains to a reduction in irrigation to allow for potable water use elsewhere. In addition, the use of proprietary engineered filter media as the filtration and stabilization medium will accommodate a significantly higher water quality treatment flow rate than existing manufactured biofilters which favorably impacts sizing criteria. Lastly, using the hydroponic design approach provides a sustainable water supply to the vegetation during those periods of time when hot and/or dry conditions may prevail.

Additional information pertaining to the accelerated high filtration flow rates that are capable using the Aqua-Ponic™ Biofiltration System as well as its sizing can be provided upon request.

Most manufactured biofiltration systems fundamentally rely on a proprietary engineered soil, medium or post-plant bed flow/filter controls to achieve 80% removal of suspended sediment from stormwater runoff (commonly known as total suspended solids, (TSS)). Other pollutants such as Total Phosphorus (TP) and total (insoluble form bound to particulate matter) and/or dissolved (soluble) heavy metals such as copper and zinc. Other metals may be targeted for removal from stormwater runoff using specialized media and/or media blends. Media mixtures are commonly utilized that contain variable percentages of engineered organic or inorganic filter media, mulch, peat moss, fine- to coarse-grained sands, gravel and rip-rap. Other engineered controls such as bypass piping, drain down piping and under drains may be incorporated as a design element. The “green” aspect of these LID-based biofilters rely on the inclusion of either high-profile or low-profile vegetation (as explained below). Some proprietary biofilters can additionally incorporate aspects of infiltration to address a fundamental LID principle of runoff reduction. In essence, these manufactured biofilters are commonly utilized as a decentralized stormwater LID product as opposed to the use of larger scale public domain swale (or bioswale) or other land-based Stormwater Control Measures (SCM) specified for runoff reduction and water quality. Some urban sites are not conducive for a large scale, centralized bioswale; hence, manufactured biofilters can fill an important role within a LID-based stormwater design.

Proprietary biofilters can be classified as either a “tree box” (vault-based) or as a linear “planter.” The Aqua-Ponic™ system is classified as a planter type biofilter designed to be consistent with GI infrastructure definitions. A planter biofilter typically utilizes hardy low-profile perennial vegetation such as native grasses, shrub grasses and/or ornamental flowering plants. Planters can utilize a single type of plant or a mixture of plants can be used to enhance the view scape with a variety of vegetation. Planters can have an aspect of infiltration when site conditions allow; however, care should be taken such that the planter can sustain the vegetation during dry weather conditions. In contrast, a tree box commonly includes a higher-profile woody, moderate-size tree, shrub, or a combination of such plants but typically do not include a wide mixture of plants. A variety of plants can also be used and tailored to the climate of a given locale. A tree box can operate in the absence of vegetation when installed underground, particularly when used for decentralized infiltration should site conditions not warrant the use of plants. Whether a planter or tree box biofilter, it is important to specify plants that demonstrate viability within the climatic zone of a site installation.

Biofilters convey water downward under gravity flow conditions, often with runoff water entering the device from a curb inlet, curb cut or surface sheet flow. It is possible that a biofilter could be installed as an end-of-pipe device but the runoff flow rate and conveyance piping should be considered for the typical lower operating flow rates of these devices. Biofilters most commonly operate at a surface area loading rate ranging from 1.0 to 2.0 gallons per minute per square foot of treatment area (gpm/ft2), or infiltration rates on the order of 125 to 175 inches per hour (in/hr). These loading and infiltration rates are commensurate with public domain designs for centralized bioswales.

A unique advantage of the Aqua-Ponic™ system is its capability to provide water quality treatment at an accelerated or exponentially higher operating rate when compared to other manufactured or land based biofiltration systems. Additional information pertaining to Aqua-Ponic™ sizing can be provided on request.